BOILERS

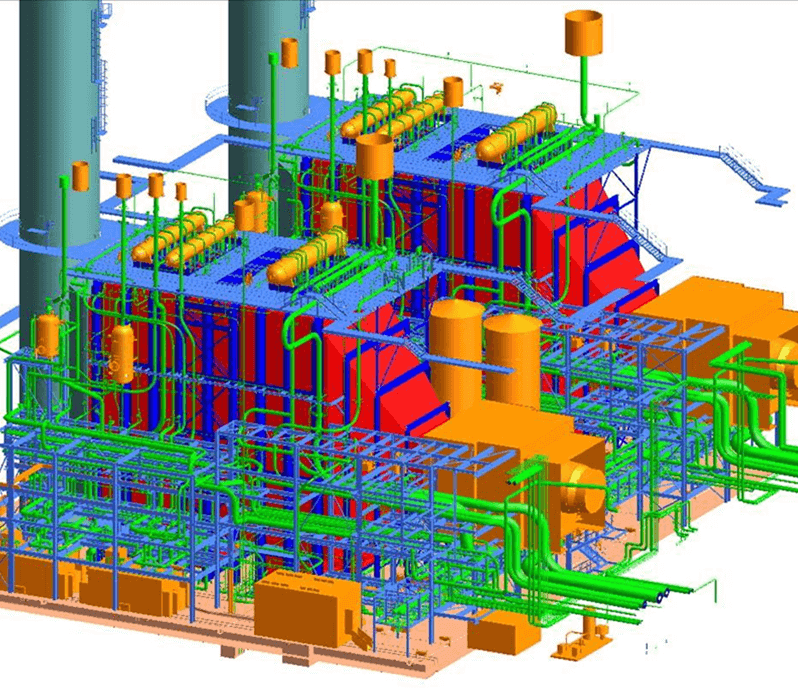

Heat Recovery Steam Generators

Gas turbines

Gas turbines

- Utility concept (up to any size)

- Industrial concept (20 - 170 MWe)

- Gas engines (large installations)

- Customised design

Large variability of standard solutions

- Vertical or horizontal

- Single, double or triple pressure with reheat; DH circuit

- Hot water applications

- Supplementary / Fresh air firing

- Various erection concepts – „O“/“C“ modules, bundles or loose harps

- SCR and/or CO catalyst

Special Gas/Oil Fired Boilers

-

- Range of application

- D–type – bi-drum packaged boilers - 40 – 250 t/h, up to 80 bar(a)

- CoGB Compact Design – modular concept - 40 – 200 t/h, 40 – 140 bar(a)

- Field Erected - 80 – 600 t/h, 40 – 175 bar(a)

- Hot Water - 50 – 250 MWth, 10 – 25 bar(a)

- Special gaseous and liquid fuels such as blast furnace gas, coke-oven gas, hydrogen, heavy fuel oil, coking tar and other waste fuels and fuel combinations

- Bottom or top Supported

- Primary De-NOx and SCR/SNCR systems

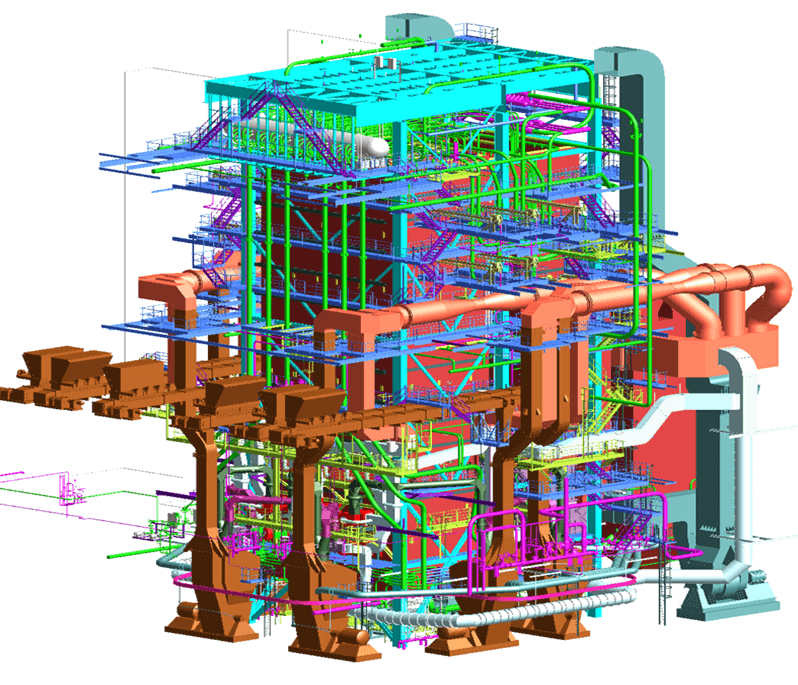

Coal Fired Boilers

Grate Firing

Grate Firing

Pulverized Coal Firing (Dry or Wet Bottom)

Fluidized-bed Firing

- Range of application: 30 – 500 t/h, 40 – 175 bar (a)

- Wide Range of Coal Quality Experience

- Re-heat steam system

- Bottom or Top Supported

- Primary De-NOx

- SCR/SNCR Systems

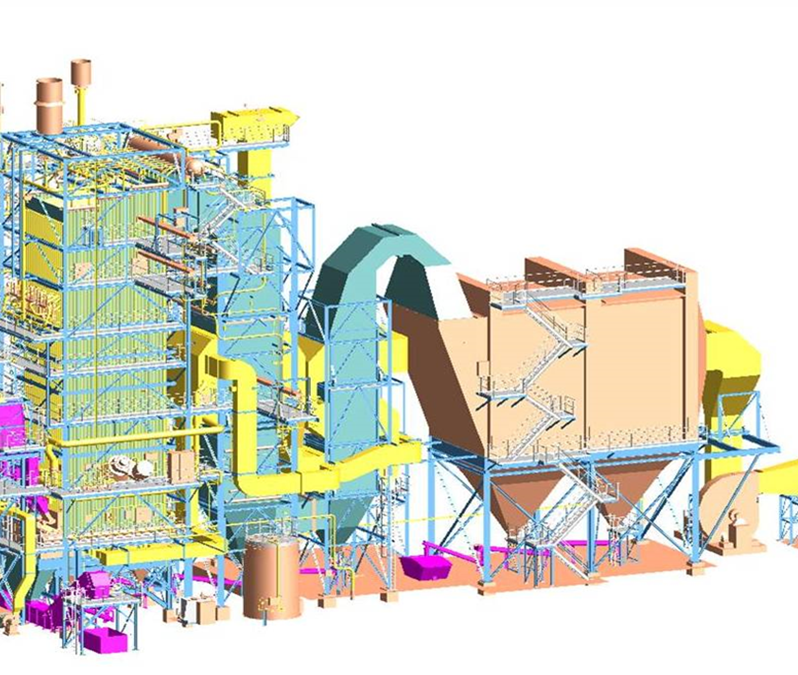

Clean Biomass Fired Boilers

Grate Firing

Grate Firing

Fluidized-bed Firing

- Range of application: 30 – 200 t/h, 40 – 140 bar (a)

- Different Biomass Fuels such as Wood Chips and Pellets, Sawdust, Straw, Bark, Pulpwood, Cardboard and other Biomass Residues including Agriculture.

- Coal as a Support/Substitute Fuel

- Bottom Supported

- Primary De-NOx

- SCR/SNCR Systems

RECONSTRUCTIONS AND OPERATIONAL IMPROVEMENTS

We have extensive experience in the field of power plant brownfields, including the integration of new equipment into existing systems. We modernise existing power plants and heating plants and provide servicing for individual equipment. We specialise in boiler reconstruction – increasing the output or operating parameters of existing equipment; improving efficiency and/or operating characteristics, including fuel base modifications and/or additional combustion with complete emission control. We manufacture more environmentally friendly boilers and increase the flexibility and efficiency of the equipment. Our company is highly qualified in the field of NOx emission reduction using state-of-the-art primary measures (low-emission burners, combustion air staging and complex modernization of fuel preparation system) and/or secondary measures (SCR or SNCR). Repair/replacement of damaged parts and components at the end of their service life is part of our range of services.

VARIETY OF SERVICES

- Conceptual/Basic Design → Equipment Deliveries → Site Assistance

Broad portfolio of design only services is also part of activities. We offer elaboration of feasibility studies, documentation of technology plant systems for state authority approvals and/or plant conceptual or basic design documentation including project documentation system management. If desired so we also supply boiler design documentation alternatively including notified body approvals for further use by third parties. We can also assist our partners with loose equipment supply (typically boilers) and site construction technical assistance only or support third party construction site with expertise of our site managers and commissioning engineers. We support renovations carried out by third parties.

- After Sales Service / Tests & Diagnostics

After sales services is an integral part of our customer support starting from personnel training, technical consultancy and/or equipment performance measurement and following throughout the whole plant life cycle with trouble-shooting support, regular inspections.

As part of testing and diagnostics, we perform technical inspections of boilers, inspections and consultations directly at the installation site. We offer warranty measurements and/or measurements of other operational characteristics including diagnostics and equipment analysis such as residual life-time assessment. We are certified for emission measurements.